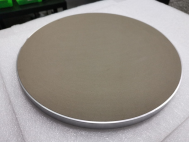

Vacuum Chuck

Vacuum Chuck (More)

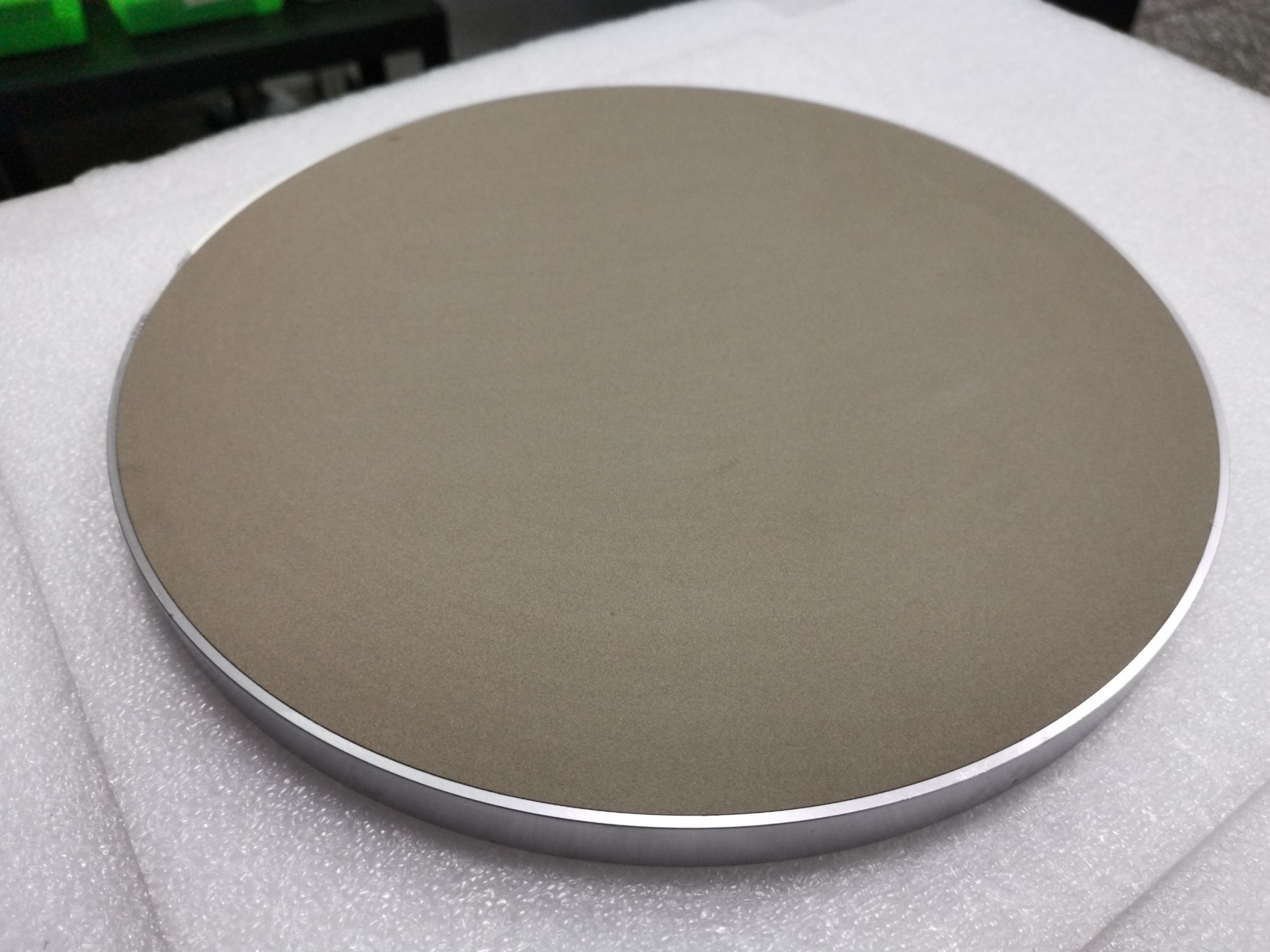

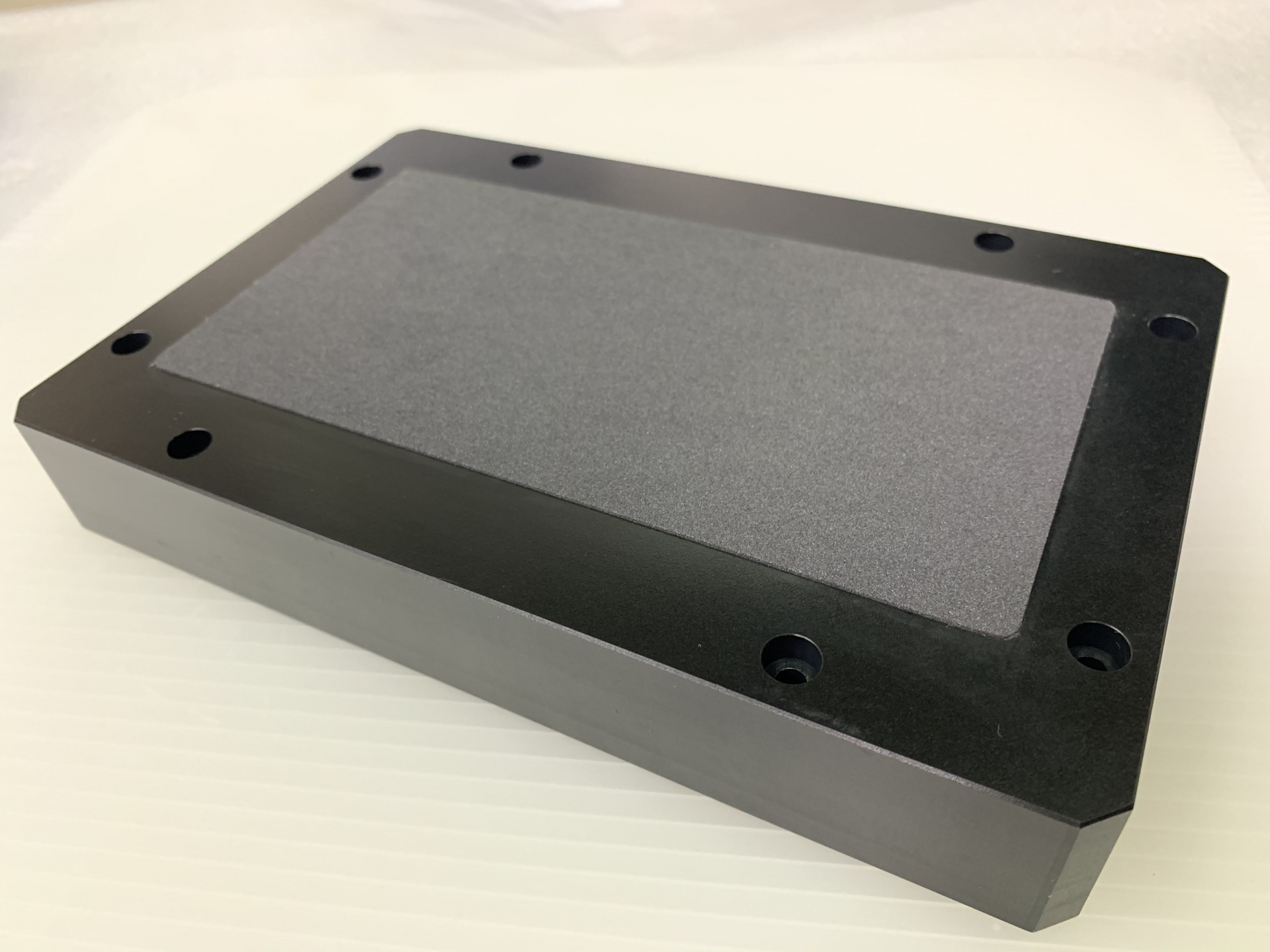

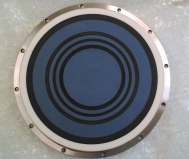

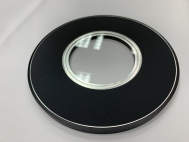

Vacuum Chuck was mainly made of porous ceramic and frame. It can also be called Porous Ceramic Vacuum Chuck, and it has two features.

1. Vacuum Chuck can absorb the workpieces in working progress.

2. Vacuum Chuck can up-floating the workpieces by working with air floating stage and non-touch transfer system.

Theory

1. When the airflow setting is sending out of ceramic (negative vacuum pressure), it can absorb the workpieces.

2. When the airflow setting is sending in of ceramic (positive vacuum pressure), it can blow up the workpieces or no-contacting with ceramic.

Application

Semi-conductor Industrial can use on:

1. Wafer Transportation

2. Wafer Dicing

3. Laser Dicing

4. Wafer Grinding

5. Wafer Cleaning

Optoelectronics Industrial can use on:

1. Pick and Place Chuck

2. Bonding the Platform

3. Air Float Axis

4. Non-Touch Transfer Platform

Vacuum Chuck's Features

1. Can absorb the warped or hollowed-out workpieces

2. Can absorb a variety of different size

3. The minimum pore size can reach 2μm, and its delicate flat can contact with workpieces without leaving any scratch

4. Excellent mechanical strength

5. Can operate at high temperature

6. Antistatic

7. Chemical Resistance

LONGYI PRECISION:

12 inch Chuck Table Measuring

Ceramic Vacuum Chuck

Washing Chuck Table

Chuck Table Repair

Vacuum Chuck

Air Bearing

About flatness/parallelism

Generally, vacuum chucks must have a frame and porous ceramics to meet the requirements of flatness/parallelism. It will also vary depending on the material of the frame. The material of the frame can be divided into 4 types, aluminum, stainless steel, granite and engineering plastic. LONGYI can provide customized services.

About Porous Ceramic

For porous ceramic, the microstructure is made up of small crystals called grains. In general, the smaller the grain size, the stronger and denser is the ceramic material. The wide variety of applications for porous ceramic materials results from their unique properties. In many respects, these properties cannot be achieved by other materials.

Processing

What is the future of porous ceramic?

For many years, the presence of porosity in ceramics was often seen to be problematic and a significant scientific effort was made to devise processing routes that produced ceramics with zero porosity. An exception to this philosophy was the refractory industry, in which it was understood that the presence of porosity is critical in controlling thermal conductivity.

Challenge

The challenge now is for materials scientists to produce ceramics with the porosity of any fraction, shape, and size. This also leads to new directions in the scientific understanding of the porous structures field.

Porous Ceramic Material

A-2000

Material: Alumina Color: White

Al2O3%: ~96% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 35~40% Bulk Specific: 2.28 g/cm3

B-2000

Material: Alumina Color: Black

Al2O3%: ~92% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 35~40% Bulk Specific: 2.28 g/cm3

C-2000

Material: Alumina Color: White

Al2O3%: ~96% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 32~40% Bulk Specific: 2.28 g/cm3

D-2000

Material: Alumina Color: Black

Al2O3%: ~95% Water%: 0%

Pore Size: 30~40um Bending: >4kgf/cm2

Porosity: 40~50% Bulk Specific: 2.1 g/cm3

Specification

Ceramic Rough Raw Material

Item No. L W H

M-CER-RE-A-01 380 250 10

M-CER-RE-A-02 430 430 6

M-CER-RE-A-03 590 510 10

M-CER-RE-A-04 680 350 10

M-CER-RE-A-05 590 510 13

M-CER-RE-A-06 680 350 13

After Precision Machining

Circle

Item No. / Dia (mm) Dia H Flatness

M-CER-APM-A-D01 103 04 0.01

M-CER-APM-A-D02 130 05 0.01

M-CER-APM-A-D03 155 05 0.01

M-CER-APM-A-D04 205 05 0.01

M-CER-APM-A-D05 256 08 0.02

M-CER-APM-A-D06 306 08 0.02

Square

Item No. / Dia (mm) L W H Flatness

M-CER-APM-A-D01 375 245 08 0.01

M-CER-APM-A-D02 425 425 04 0.01

M-CER-APM-A-D03 585 585 08 0.02

M-CER-APM-A-D04 675 345 08 0.02

M-CER-APM-A-D05 585 505 11 0.02

M-CER-APM-A-D06 675 345 11 0.02

Ceramic Vacuum Chuck

We have excellent quality and workmanship

Item No. / Dia (mm) Inch Flatness

CPC-SS-04 4" 0.005

CPC-SS-06 6" 0.005

CPC-SS-08 8" 0.005

CPC-SS-12 12" 0.005

Porous Ceramic Vacuum Chuck

Item No. / Dia (mm) L W H Flatness

C-PRO-GB-010 100 100 28 0.01

C-PRO-GB-020 200 200 28 0.01

C-PRO-GB-025 250 250 28 0.01

C-PRO-GB-030 300 300 30 0.01

C-PRO-GB-040 400 400 30 0.02

C-PRO-GB-1000 1000 1000 250 0.03

C-PRO-GB-1500 1500 1500 250 0.05

Vacuum Chuck was mainly made of porous ceramic and frame. It can also be called Porous Ceramic Vacuum Chuck, and it has two features.

2. Vacuum Chuck can up-floating the workpieces by working with air floating stage and non-touch transfer system.

Theory

1. When the airflow setting is sending out of ceramic (negative vacuum pressure), it can absorb the workpieces.

2. When the airflow setting is sending in of ceramic (positive vacuum pressure), it can blow up the workpieces or no-contacting with ceramic.

Application

Semi-conductor Industrial can use on:

1. Wafer Transportation

2. Wafer Dicing

3. Laser Dicing

4. Wafer Grinding

5. Wafer Cleaning

Optoelectronics Industrial can use on:

1. Pick and Place Chuck

2. Bonding the Platform

3. Air Float Axis

4. Non-Touch Transfer Platform

Vacuum Chuck's Features

1. Can absorb the warped or hollowed-out workpieces

2. Can absorb a variety of different size

3. The minimum pore size can reach 2μm, and its delicate flat can contact with workpieces without leaving any scratch

4. Excellent mechanical strength

5. Can operate at high temperature

6. Antistatic

7. Chemical Resistance

LONGYI PRECISION:

12 inch Chuck Table Measuring

Ceramic Vacuum Chuck

Washing Chuck Table

Chuck Table Repair

Vacuum Chuck

Air Bearing

About flatness/parallelism

Generally, vacuum chucks must have a frame and porous ceramics to meet the requirements of flatness/parallelism. It will also vary depending on the material of the frame. The material of the frame can be divided into 4 types, aluminum, stainless steel, granite and engineering plastic. LONGYI can provide customized services.

About Porous Ceramic

For porous ceramic, the microstructure is made up of small crystals called grains. In general, the smaller the grain size, the stronger and denser is the ceramic material. The wide variety of applications for porous ceramic materials results from their unique properties. In many respects, these properties cannot be achieved by other materials.

Processing

What is the future of porous ceramic?

For many years, the presence of porosity in ceramics was often seen to be problematic and a significant scientific effort was made to devise processing routes that produced ceramics with zero porosity. An exception to this philosophy was the refractory industry, in which it was understood that the presence of porosity is critical in controlling thermal conductivity.

Challenge

The challenge now is for materials scientists to produce ceramics with the porosity of any fraction, shape, and size. This also leads to new directions in the scientific understanding of the porous structures field.

Porous Ceramic Material

A-2000

Material: Alumina Color: White

Al2O3%: ~96% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 35~40% Bulk Specific: 2.28 g/cm3

B-2000

Material: Alumina Color: Black

Al2O3%: ~92% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 35~40% Bulk Specific: 2.28 g/cm3

C-2000

Material: Alumina Color: White

Al2O3%: ~96% Water%: 0%

Pore Size: 2~3um Bending: >6kgf/cm2

Porosity: 32~40% Bulk Specific: 2.28 g/cm3

D-2000

Material: Alumina Color: Black

Al2O3%: ~95% Water%: 0%

Pore Size: 30~40um Bending: >4kgf/cm2

Porosity: 40~50% Bulk Specific: 2.1 g/cm3

Specification

Ceramic Rough Raw Material

Item No. L W H

M-CER-RE-A-01 380 250 10

M-CER-RE-A-02 430 430 6

M-CER-RE-A-03 590 510 10

M-CER-RE-A-04 680 350 10

M-CER-RE-A-05 590 510 13

M-CER-RE-A-06 680 350 13

After Precision Machining

Circle

Item No. / Dia (mm) Dia H Flatness

M-CER-APM-A-D01 103 04 0.01

M-CER-APM-A-D02 130 05 0.01

M-CER-APM-A-D03 155 05 0.01

M-CER-APM-A-D04 205 05 0.01

M-CER-APM-A-D05 256 08 0.02

M-CER-APM-A-D06 306 08 0.02

Square

Item No. / Dia (mm) L W H Flatness

M-CER-APM-A-D01 375 245 08 0.01

M-CER-APM-A-D02 425 425 04 0.01

M-CER-APM-A-D03 585 585 08 0.02

M-CER-APM-A-D04 675 345 08 0.02

M-CER-APM-A-D05 585 505 11 0.02

M-CER-APM-A-D06 675 345 11 0.02

Ceramic Vacuum Chuck

We have excellent quality and workmanship

Item No. / Dia (mm) Inch Flatness

CPC-SS-04 4" 0.005

CPC-SS-06 6" 0.005

CPC-SS-08 8" 0.005

CPC-SS-12 12" 0.005

Porous Ceramic Vacuum Chuck

Item No. / Dia (mm) L W H Flatness

C-PRO-GB-010 100 100 28 0.01

C-PRO-GB-020 200 200 28 0.01

C-PRO-GB-025 250 250 28 0.01

C-PRO-GB-030 300 300 30 0.01

C-PRO-GB-040 400 400 30 0.02

C-PRO-GB-1000 1000 1000 250 0.03

C-PRO-GB-1500 1500 1500 250 0.05

- About usLONGYI

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

- Products

- Download

- Technology and Service

- Advanced Ceramic & Fine Ceramic

- Contact Us

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan│Tel : +886-3-466-6611│Fax : +886-3-466-7722

|

Designed by MIRACLEWeb Design