Ceramic Arm/End Effector

Production information

The end effector (ceramic robot hand) constitutes the end of the robot arm which handles and moves the semiconductor wafer between positions. It’s basically the robot’s hand so it is important that it be thermally and dimensionally stable and not contaminate the chamber with particles or chemical contaminants.

Ceramic Arms are used to manipulate and carry silicon wafers through the whole production in the semiconductor process. It enables the handling of large-size wafers and can be designed with vacuum channels in order to hold the part.

Ceramic Arms are used to manipulate and carry silicon wafers through the whole production in the semiconductor process. It enables the handling of large-size wafers and can be designed with vacuum channels in order to hold the part.

In robotics, an end effector is a device or tool that's connected to the end of a robot arm where the hand would be. The end effector is the part of the robot that interacts with the environment. The structure of an end effector and the nature of the programming and hardware that drives it depends on the task the robot will be performing. If a robot needs to pick something up, a type of robot hand called a gripper is the most functional end effector.

Ceramics have superior mechanical, electrical, and thermal properties ideal for quality components. The durability of fine ceramics makes it ideal for mechanical and thermal loads that are abrasive and in a chemically harsh environment.

Ceramic Arm | Ceramic End Effektor Specification

MATERIALS :

Alumina Antistatic Ceramic

Zirconia Silicon Carbide

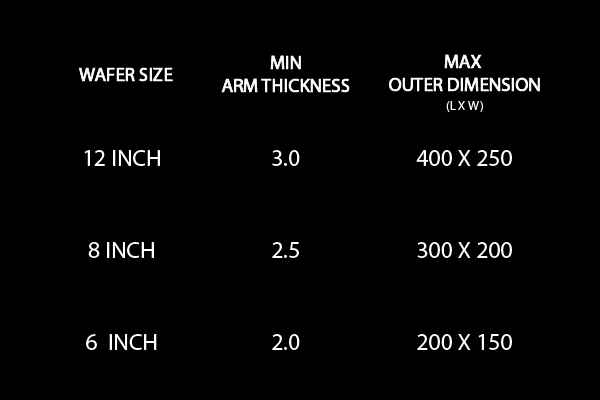

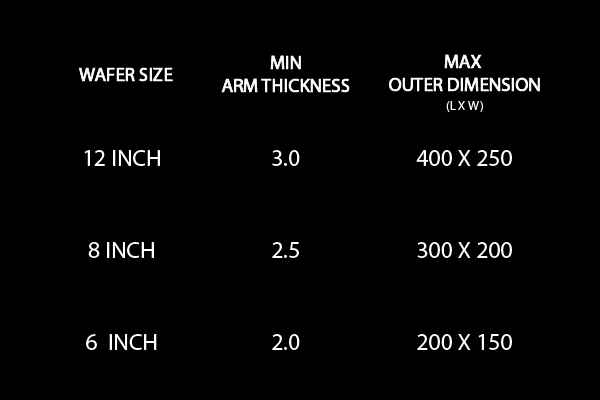

SIZING :

↓FOR CUSTOMIZED ORDERS PLEASE SEE SIZING REFERENCE ↓ USAGE :

USAGE :

– MOVING

– MAPPING

SPECIFICATION :

flatness & tolerance : 0.05 mm

color : white

HOW ITS MADE :

GRINDING

CNC

In robotics, an end effector is a device or tool that's connected to the end of a robot arm where the hand would be. The end effector is the part of the robot that interacts with the environment. The structure of an end effector and the nature of the programming and hardware that drives it depends on the task the robot will be performing. If a robot needs to pick something up, a type of robot hand called a gripper is the most functional end effector.

Ceramics have superior mechanical, electrical, and thermal properties ideal for quality components. The durability of fine ceramics makes it ideal for mechanical and thermal loads that are abrasive and in a chemically harsh environment.

Ceramic Arm | Ceramic End Effektor Specification

MATERIALS :

Alumina Antistatic Ceramic

Zirconia Silicon Carbide

SIZING :

↓FOR CUSTOMIZED ORDERS PLEASE SEE SIZING REFERENCE ↓

– MOVING

– MAPPING

SPECIFICATION :

flatness & tolerance : 0.05 mm

color : white

HOW ITS MADE :

GRINDING

CNC

CMM measurement system has contact probe (3D) and non-contact imaging (2.5) functions, making the measurement report more realistic and completely different from "handwritten" QC reports.

- About usLONGYI

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

- Products

- Download

- Technology and Service

- Advanced Ceramic & Fine Ceramic

- Contact Us

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan│Tel : +886-3-466-6611│Fax : +886-3-466-7722

|

Designed by MIRACLEWeb Design