Ceramic Metallization

CERAMIC METALLIZATION

Advanced ceramic has distinctive properties, thus it can be joined with metals. Before joining with metal the ceramic needs to be metalized (thin-coating it with metal material which provides an interface for brazing). Then brazed, which creates a vacuum tight, robust joint between ceramic and metal.

CERAMIC THAT'S OFTEN METALIZED

Alumina (Al2O3), because of its electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance and low thermal expansion.

Aluminum Nitride (AlN), because of its thermal conductivity, thermal expansion coefficient, and electrical insulation.

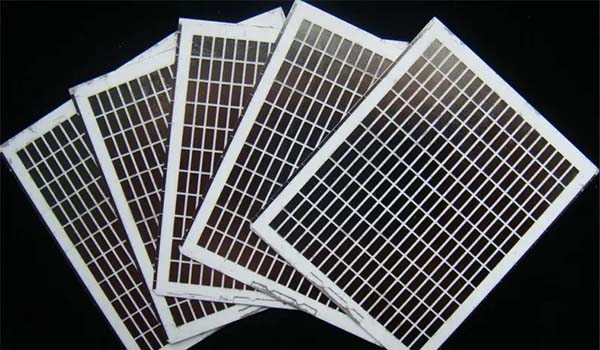

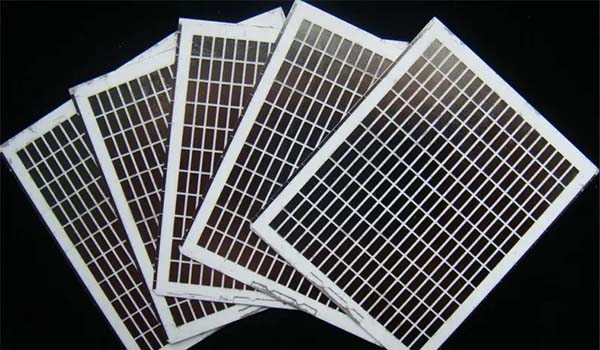

metallization ceramic

Metallization ceramic

HOW IS IT METALIZED?

With our technology, we utilize Moly-Manganese formula as coatings to make a strong bond with brazing agents.

After applying the ink formula,in a hydrogen/nitrogen controlled atmosphere, they are fired at a temperature of 1300 to 1500°C.

APPLICATIONS

High voltage ceramic plates

Vacuum electron devices

Bio-compatible implantable devices

Lasers

Available Ceramic Compositions Al2O3 94%, 96%,

Metallization Materials Mo/Mn

Metallization Thickness 25um ±10um

Advanced ceramic has distinctive properties, thus it can be joined with metals. Before joining with metal the ceramic needs to be metalized (thin-coating it with metal material which provides an interface for brazing). Then brazed, which creates a vacuum tight, robust joint between ceramic and metal.

CERAMIC THAT'S OFTEN METALIZED

Alumina (Al2O3), because of its electrical insulation, high thermal conductivity, high chemical resistance, good wear resistance and low thermal expansion.

Aluminum Nitride (AlN), because of its thermal conductivity, thermal expansion coefficient, and electrical insulation.

metallization ceramic

Metallization ceramic

HOW IS IT METALIZED?

With our technology, we utilize Moly-Manganese formula as coatings to make a strong bond with brazing agents.

After applying the ink formula,in a hydrogen/nitrogen controlled atmosphere, they are fired at a temperature of 1300 to 1500°C.

High voltage ceramic plates

Vacuum electron devices

Bio-compatible implantable devices

Lasers

Available Ceramic Compositions Al2O3 94%, 96%,

Metallization Materials Mo/Mn

Metallization Thickness 25um ±10um

- About usLONGYI

- News

- Antistatic-ceramic suction cups officially enter the KLA supply system

- Chinese New Year Celebration Announcement

- Since the epidemic of COVID-19 is serious, the production staffs work separately by turns. Delivery time must be affected by process extension.

- Porous Ceramic Vacuum Chuck + Granite Base

- Company relocation notice

- Ceramic characteristics

- Ceramics Gas Tube ASSY

- Die bonder Dispensing Pin 45mil D/B

- Fittings

- Ceramic Ferrule

- Tokyo Weld / Tester / Packaging Machine / Ceramic Index table

- Ceramic Nozzle

- Ceramic Nozzle

- Ceramic Nozzle

- Die bonder Dispensing Pin D/B

- Porous ceramic vacuum chuck

- Advanced Ceramic & Fine Ceramic

- Products

- Download

- Technology and Service

- Advanced Ceramic & Fine Ceramic

- Contact Us

|

LONGYI PRECISION TECHNOLOGY CO., LTD.

Address : No. 705, Longxing Road, Chungli District , 32091, Taoyuan, Taiwan│Tel : +886-3-466-6611│Fax : +886-3-466-7722

|

Designed by MIRACLEWeb Design